Are you prepared to get on the ground of trencher machines? Catering to the installation of the utilities like water, electricity, and any other types of utilities at home or making a landscape project come to life, these powerful tools can make a big difference. Whether it is laying pipelines or digging up trenches to install irrigation systems, one cannot go without a trencher in an employment site. Considering the advancement of construction technology, it becomes much more significant to know what trenchers exist and what they can do.

This guide will discuss everything you should know about trencher machines, namely the ones that are provided by Sunstate Pipelines. As a contractor seeking new equipment or reader interested in how the equipment works, you will find useful information here. Get prepared to know all the details of trenching!

The Different Types of Trenchers

There are different varieties of trencher machines, each one performs different tasks. Chain trenchers are the most popular. These possess a rotating chain of metal with sharp teeth that provides effective ability to cut through soil and rock.

There are the wheeled trenchers that are mobile and run on softer grounds with speed. They ride on rubberized tires to negotiate with ease making thin grooves.

Rock trencher might be considered on more difficult jobs. This type is endowed with heavy blades that make them to cut through rocky grounds easily and precisely.

Mini trenchers are versatile on small jobs or narrow applications where a larger machine can not be used. Their miniature natures enable them to dig shallow trenches that do not interfere too much with an adjacent space.

The knowledge of the various types assists in choosing the appropriate trencher machine. sunstate pipelines trencher machines adequately cater to this diversity so that you can find an ideal one regardless of the size and difficulty of the project.

Uses and Benefits of Trencher Machines

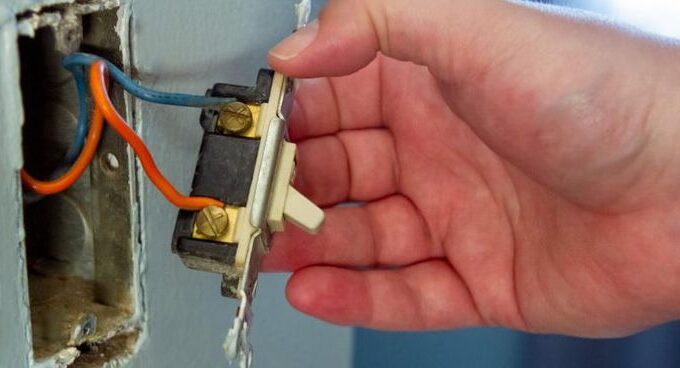

Trencher machines exert a wide range of applications and cover different excavation jobs. They are specialists in trench digging (pipelines, water, and electrical work). Their accuracy eliminates wastage of time and eliminates the use of human labor.

These machines are supplied with varying sizes of blades so as to enable them meet projects of varying depths. This versatility renders them suited to use both in the residential area and large-scale construction sites.

Trenching with a trencher machine is safer as much of the danger, posed by a more primitive way of trenching, is alleviated. Operators will be able to work faster and minimize physical impressions

The other immense advantage is cost-effectiveness. Trenchers are useful in reducing the costs and timelines of the labor as they make the installation process faster.

Besides their efficiency, the machines tend to be less expensive to operate than their alternatives available in the market. Modern trenchers are proving even more efficient as technology advances and they remain at a very affordable price without compromising on quality.

Factors to Consider Before Purchasing a Trencher Machine

Various factors are involved when it comes to deciding to purchase a trencher machine. The first thing is to review the nature of the projects you deal with. Trenching capabilities vary according to several jobs.

Then evaluate your budget. The prices of the trenching machines greatly differ depending on their specification and capability. Make sure you get a model that is cost effective and still not compromised on quality.

Take into account the size and weight of the machine also. A compact model might be more appropriate, especially, when you are going to be squeezing into narrow spaces, or taking it with you frequently.

Pay attention to the sources of power not to overlook them as well. Others are diesel-driven and others are electricity- or gas-operated. Select one that would suit your operational requirements, and site circumstances.

Consider what sort of warranties and option to support is offered by manufacturers such as Sunstate Pipelines Trencher Machines to know that you will have peace of mind after making a purchase.

Maintenance and Safety Tips for Operating a Trencher

Maintenance and safety entails a lot of diligence when operating a trencher. Before using the machine, inspect it each and every time At the belts, check the loose bolts and worn belts and any observed hydraulic leakages.

C.(– phases) Use proper personal protective equipment (PPE). These would be gloves, hard hats and steel-toed boots. The safety goggles are mandatory, as it is important to preserve the safety of the eyes.

Keep up the work place free. Remove anything that can lead to any accidents or something to hinder operation. There is also need to mark the underground utilities prior to starting the digging.

In running the trencher, keep a smooth going. Sudden movements may result in loss of controls or even damages on the machine and should be avoided.

Home and service your trencher as per the correct guidelines provided by the manufacturer Ensuring proper maintenance extends its life span and offers the best performance during such key projects such as sunstate pipelines trenching.

Innovative Features of Modern Trencher Machines

Unlike in the earlier days, modern trencher machines have advanced much in both advancement and efficiency. The latest designs have some innovative features that are a vast improvement in performance and usability.

GPS technology is one prominent feature whereby the operators are able to accurately plot trench lines. This precision reduces the necessity of rework and also keeps projects in schedule. Moreover, hi-tech hydraulics systems allow the equipment to operate without jerks, offering increased control of the cutting depth and speed.

Environmentally-friendly engines that have low emissions but are very powerful are also fitted in some of the trencher machines. Such a focus on sustainability is not only beneficial to the environment, but also satisfies regulatory requirements in a more readily achievable way.

The other important innovation is the remote control ability Operurers would have a better distance management handle their trenchers, enhancing safety at the construction sites where the risk could be present.

Also, most of the modern trenchers have modular attachments which enable the user to change to various tasks in the shortest time possible. Whether it be excavating trenches to put in drainage systems or to put in pipelines the versatility is what is essential in these work settings where time is always of the essence.

The innovations indicate the continuous efforts in the sector to ensure that improved productivity is realized without compromising the safety of the workers in different sectors including those interested in Sunstate pipelines trencher tools. These technologies are changing quite rapidly offering even more promising inventions in the world of construction equipment.

Leave a comment